buy prednisolone 5mg

prednisolone cost

charamin.com prednisolone dosage

benadryl and pregnancy third trimester

benadryl and pregnancy nausea

blog.icuracao.net

Group Leader

Dr Hamid Rashid

Dy. Chief Scientist

Team members:

- Dr Saira Bashir (Principal Scientist)

- Dr Hazrat Ali (Principal Scientist)

- Engr. Ambreen Latif (Senior Engineer)

- Dr Noor Hassan (Senior Scientist)

- Mr. Asad Ali (Junior Scientist)

- Mr. Maqsood Ahmad (Principal Scientific Assistant)

- Mr Khalid Yaqub (Principal Scientific Assistant)

- Mr Sarwar (Principal Tech)

- Mr Naveed Anwar (Principal Tech)

- Mr. Sarfraz A. Nouman (Scientific Assistant-II)

- Mr Naveed (Scientific Assistant-II)

Industrial Enzymes and Biofuels (IE&B) group is dedicated for strain development to enhance the production of industrial enzymes including cellulase, xylanase, ?-amylase, glucoamylase, phytase, pectinase, protease and lipase for feasibility in animal feed, textile, pulp and paper, detergent and food industry. IE&B has tool box of enzyme engineering using rational protein design and directed evolution for enhancing catalytic activity of commercially important enzymes and immobilization on nano-materials for application in food and livestock feed industry. In this research group, the research objectives have further been categorized into three themes i.e. industrially important enzymes production (Dr. Muhammad Hamid Rashid), Molecular intervention for strain improvement (Dr. Hazrat Ali) and Nutraceutical production (Dr. Muhammad Hamid Rashid and Dr. Hazrat Ali).

Industrially important enzymes production

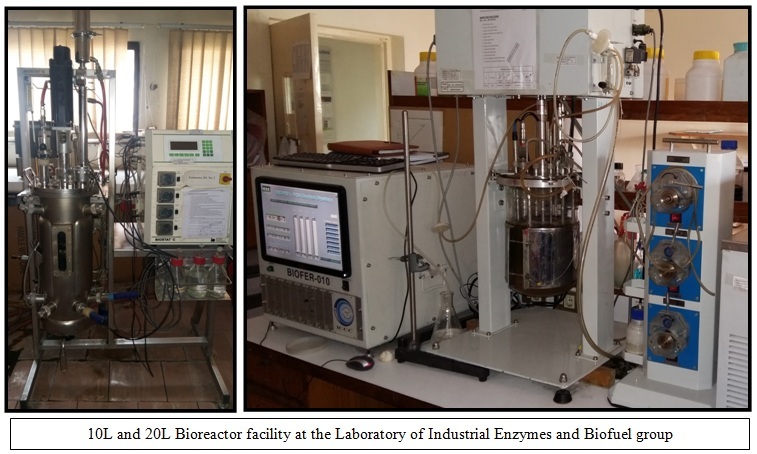

At Industrial Enzymes and Biofuel group (IEB), NIBGE, the super Koji (A. oryzae) is cultivated in 10 L bioreactor (fermenter) for the optimum production of Koji enzymes like: cellulases and alpha-amylase. Rafhan Maize Products, Faisalabad is testing these enzymes for the semi pilot scale maltose syrup production at Rafhan Maize Products. As Rafhan Maize, Faisalabad is producing maltose syrup from corn starch by using alpha-amylase, which is solely imported from foreign countries. NIBGE is in collaboration with Rafhan Maize for the evaluation of its developed alpha-amylases.

After successful optimization of growth conditions in 140 L Fermenter at NIBGE, an agreement will be signed with Auriga Group of Companies, Lahore for the process scale up to 5000 L Fermentation. The industrial scale up- and downstream processing facility is available at Auriga Group of Companies, which will be used for the production of Koji’s enzymes at Industrial scale. Marketing of food and feed enzymes with NIBGE ORIC office will be carried out after doing the necessary formalities (Agreement or MoU will be signed between NIBGE & Auriga)

Molecular intervention for strain improvement

The proposed project aims to develop methodologies for development of a host strain that has the capability of diverting the metabolic flux toward a targeted biosynthetic pathway for enhance production. Here the primary target is the production of iturin A and its analogues with reduced toxicity after tuning the biosynthesis pathway. We plan to exploit the superb fermentation characteristics of Bacillus subtilus in conjunction with enzyme engineering approaches for the production of a variety of natural and unnatural iturin-A related compounds. We will generate a host strain that lacks the entire fengycin and surfactin gene clusters, and re-introduce the complete and incomplete iturin-A biosynthetic gene on a plasmid to enable high level production of various intermediates and end products.

In addition, we will rearrange the adenylation domain schematically for the biosynthesis of modified final products and intermediates with the aim to improve upon the antimicrobial activity and to reduce toxicity10. Advanced analytics (LC-MS/MS) will be employed to characterize the purified compounds that will be thoroughly tested for antimicrobial screening.

The deliverables of the program are fermentation-based and combinatorial protein engineering schemes for the production of natural and unnatural iturin-A related metabolites and an inventory of their antifungal activities.

Production of Neutraceuticals:

To reduce the antibiotics load in poultry feed attempt has been made to develop an alternative. Single cell proteins (Pitchia pastoris, Saccharomyces cerevisiae, Aspergillus oryzae) and a blend of enzymes (Cellulase, Phytase, Xylanase) proved to be the alternative to enhance the growth in livestock. Attempts have been made to enhance the cell biomass production of Pitchia pastoris, Saccharomyces cerevisiae and Aspergillus oryzae and developing cost effective methodologies for production of single cell proteins at industrial scale. Recently, Aspergillus orzyae genome has been explored in this connection. Human analog Ku 70 gene has been identified and deletion vectors will be constructed to remove non homologous end joining (NHEJ) mechanism. This will open its genome for further intervention.

The specific objectives of our research are:

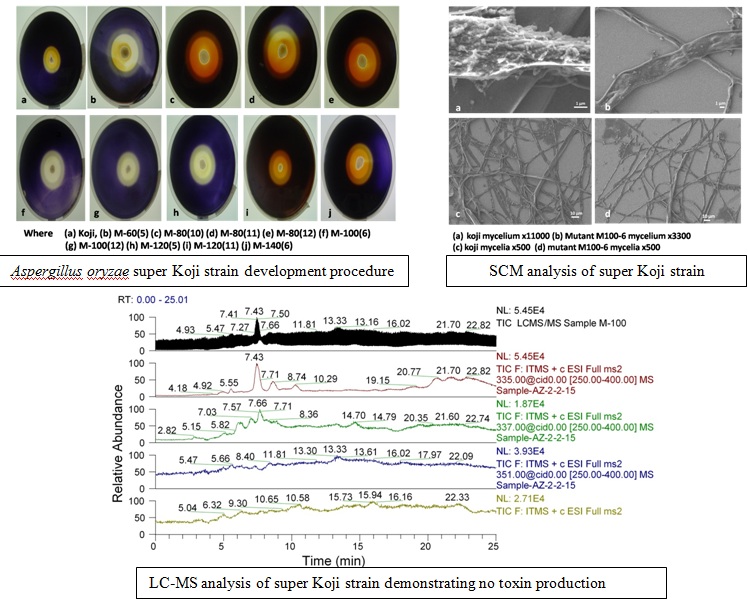

v Super Koji (Aspergillus oryzae) was developed for the hyper production of industrial enzymes (α-amylase, cellulases, alkaline proteases, etc) for application in various industries viz: textile, paper & pulp; detergent, food & feed, etc.

v The efficacy of developed Koji a-amylase for maltose syrup production was analyzed by Rafhan Maize Products, Faisalabad and found to be okay.

v Variants of Super Koji strain were developed for starch scarification through random mutagenesis by gamma ray treatment for the hyper production of moderately thermostable a-amylases. After multistep screening, 2-deoxy D-glucose resistant mutant derivatives of Super Koji were selected, which were hyper producer of thermostable a-amylases. The half life (t½) of 100Krad-6 a-amylase at 55 °C was 52 min. The LC-MS/MS-MS analysis of a-amylases confirmed that the mutants did not produce aflatoxins, hence, are safe for application in food and feed industry.

v Single cell proteins (Pitchia pastoris, Saccharomyces cerevisiae, Aspergillus oryzae, Actinomycetes) are produced as alternative to antibiotics and their efficacy to enhance the growth in boiler chicken has been determined

Salient Facilities:

- Bioreactors (10L, 20L, 140L and 250L)

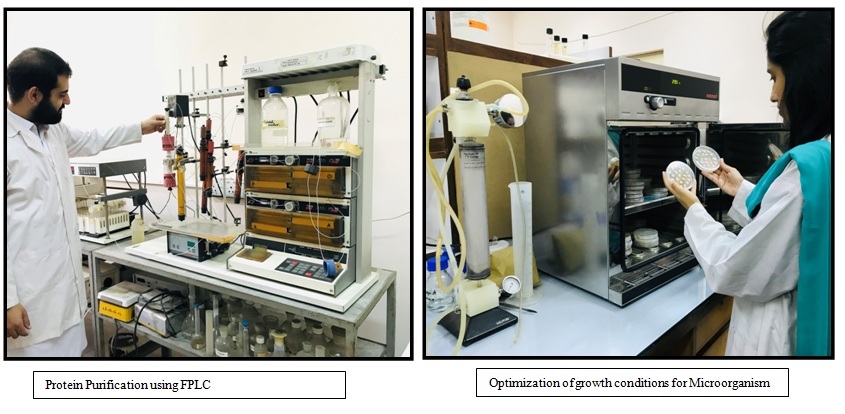

- FPLC

- Thermocycler for Standard and Gradient PCR

- Gel Electrophoresis Units for DNA and Proteins

- Sonicator

- Freeze Dryer

- Fermenter

- Shaking Incubators (4° C to 70° C)

- UV-Visible Spectrophotometers

- High performance liquid chromatography (HPLC)

Funded Research Projects:

- Enzymes production by super koji for food and feed industry; Process scaling up at pilot and industrial level. Worth PKR 14.5 millions. Funded by Higher Education Commission (HEC) of Pakistan. (Principal Investigator: Dr. Muhammad Hamid Rashid)

- Development of super koji (Aspergillus oryzae) for enhanced production of thermostable food grade enzymes for application in food and feed industry. Worth PKR 2.576 Millions. Funded by Higher Education Commission (HEC) of Pakistan. (Principal Investigator: Dr. Muhammad Hamid Rashid)

- Engineering the biosynthesis of iturin-A by non ribosomal peptide synthetase domain/module exchange in advance host strain for novel metabolites. Worth PKR 3.9 millions. Funded by Higher Education Commission (HEC) of Pakistan. (Principal Investigator: Dr. Hazrat Ali)

- Development of biological analogous of fengycin and its application against fungal pathogens in wheat. Worth PKR 3.45 millions. Funded by ALP-PARC. (Principal Investigator: Dr. Hazrat Ali)

HD photographs of Lab Activities