|

Qualification:

- PhD (Biotechnology) PIEAS, Islamabad, Pakistan.

- M.Phil. (Biotechnology) Quaid-i-Azam University, Islamabad Pakistan.

- Post Graduation (Env. Engg.) Massey University Palmerston North, New Zealand.

- M.E. (Environmental Engineering) University of Auckland, New Zealand.

- M. Sc (Environmental Sciences) NUST, Islamabad, Pakistan.

- B.Sc. (Hons) Agriculture, University of Agriculture Faisalabad, Pakistan.

Research Interest:

- Plant bacteria partnership for crude oil degradation using wetland treatment technology.

- Integrated treatment technology for industrial effluent treatment.

- Coagulation-flocculation of industrial wastewater treatment.

- Designing and fabrication of pilot scale wastewater treatment plant.

- Temporal trends of physiochemical parameters in biosolids

- Anaerobic treatment (UASB) of effluent from textile and pulp & paper Industry.

- Biosolid generation, handling and characterization.

- Role of vertical mixing and sunlight on treatment performance of waste stabilization ponds

Projects as PI:

2017-2019 ALP funded project worth Rs.3.7 M. “Integrated treatment technology for textile effluent treatment”

Research Activities:

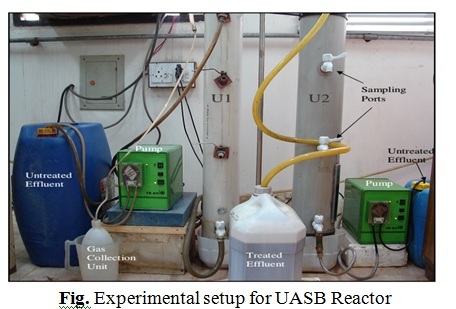

Establishment of UASB Reactor for Treatment of Wastewater

The designing, fabrication and installation of 35L capacity UASB reactor (Fig 1) was carried out. The effluent of both industries were analysed and used for the reduction of COD and BOD through UASB reactor. The comparative efficiency of self-inoculated and micronutrients provided UASB reactor was examined and results showed that an average reduction 49% and 60% in COD and BOD in case of Paper and Board Mill, and 56% & 51% in COD and BOD respectively in case of textile wastewater is achieved by self-inoculated UASB reactor.

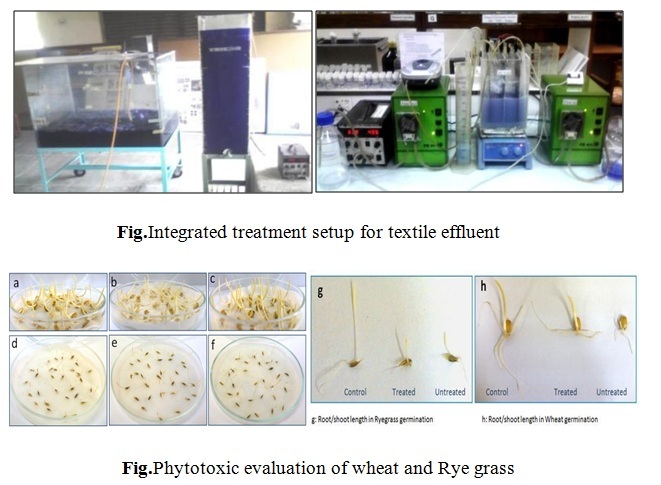

Integrated treatment technology for textile effluent and its phytotoxic evaluation

Pilot-scale wastewater treatment systems were investigated for real textile effluent. The parameters of interest in this study were color (Reactive Blue-19 dye), chemical oxygen demand, and growth potential in Triticumaestivum (wheat) and Loliummultiflorum (ryegrass). The dissolved air flotation and electrochemical treatment were studied independently as well as in combination termed as “integrated” (INTG) treatment system for comparative analysis. The overall results showed that the best treatment performance was achieved through INTG treatment as reduction of 63% in COD and 72% in color was achieved without addition of any other chemical at the current density of 1 mA/cm2 in 1 h of residence time using aluminum electrodes. The INTG-treated effluent was tested for growth potential studies (Fig 3) and the results showed that root/shoot lengths were 20/26% and 34/35% more for wheat and ryegrass, respectively, as compared to the untreated wastewater. This pilot-scale study provides evidence that INTG treatment system is a sustainable technology and the treated effluent can be reused for irrigation purposes.

Chokera wastewater treatment using wetland treatment technology:

The part of the dedicated wetland team worked at Chokera-Faisalabad, for domestic effluent treatment using floating treatment wetlands.

Fig.Wastewater treatment using floating treatment wetlands at Chokera-Faisalabad

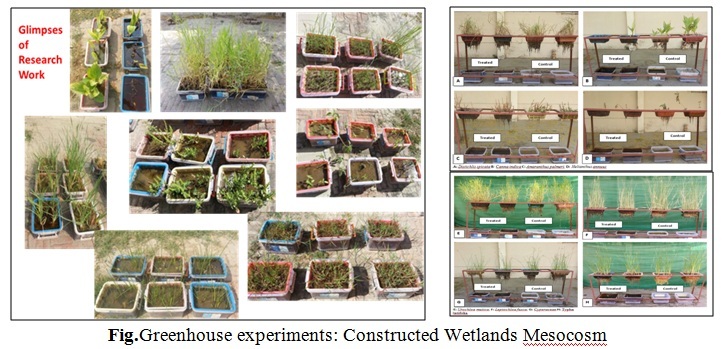

The selection of potential emergent plants grown in crude oil contaminated constructed wetlands

This study focused on the selection of suitable emergent plants in mesocosm-scale, mono-cultured constructed wetland (Fig 5). The effect of high concentration of crude oil (2% VCrude oil/Vwater) on selected wetland plants (Para grass, Kallar grass, Typha spp., Cannas spp., Sunflower, Cyperus plant, Inland saltgrass and Junglichulai) in an experimental setup of natural environmental conditions were investigated. Results showed that the highest growth and biomass production were in T. latifolia and C. laevigatus.

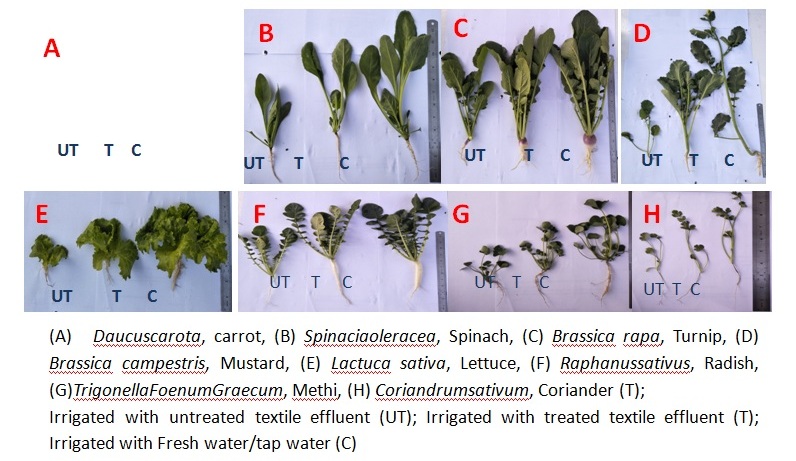

Pilot scale treatment of textile effluents using integrated treatment technology and its potential reuse for irrigation purpose

The main objective of this Agriculture Linkage Program (ALP) funded project (Worth 3.6 Million Rs, 2017-2019) is the integration of available treatment technologies i.e floating treatment wetlands (FTWs) with Upflow anaerobic sludge blanket (UASB) reactor, which can cope with textile effluent treatment offering a cost-effective, environmental friendly and safe alternative to conventional. Thus the potential of treated water is being assessed for its safe reuse as irrigation water. The comparative analysis of the vegetables irrigated with untreated, treated (Integrated treated) and fresh water (control) are shown below.

International symposium:

- I was the lead author of the work on “Enhanced degradation of diesel-originated pollutants using Phragmites-planted intensified-wetlands”. Published in 8th International Symposium on “Wetland Pollutant Dynamics and Control” held at Aarhus University Denmark (June 17-22, 2019).Available online at http://wetpol.com/about/

Completed project

- Successfully completed ALP funded project (2017-2019) as PI: “Pilot scale treatment of textile effluents using integrated treatment technology and its potential reuse for irrigation purpose”. Rs. 3.6 Million, ALP-PARC.

Short listed project: “Treatment of textile effluent using electrochemical, photocatalysis and phytoremediation for increased water productivity&reuse”. Worth Rs.7.3M. (2020-2023).

Publications (last five years):

- Hashmat, Amer Jamal, Muhammad Afzal, Carlos Alberto Arias, Carlos A. Ramirez-Vargas, and Hans Brix. "Enhanced degradation of hydrocarbons in constructed wetlands aided with nutrients, surfactant, and aeration." International Journal of Phytoremediation 24, no. 11 (2022): 1163-1172.

- Hashmat, Amer Jamal, Muhammad Afzal, Samina Iqbal, Imran Amin, Carlos Alberto Arias, Hans Brix, Imran Zafar et al. "Nutrients, surfactants, and aeration in constructed wetlands affect bacterial persistence and metabolic activity during the remediation of crude oil-contaminated water." Bioresources and Bioprocessing11, no. 1 (2024): 40.

- Amer J. Hashmat, Afzal M, Arias CA, Brix H. et al. (2019): Characterization of hydrocarbon-degrading bacteria in constructed wetland microcosms used to treat crude oil polluted water. Bulletin of Environ. Cont. and toxicol. 102, 358-364.(IF: 02)

- Afzal M, Hashmat A. J, et al.(2019): Floating treatment wetlands as a suitable option for large-scale wastewater treatment. Nature Sustainability 2, 863-871.(IF: 12)

- Afzal M, Hashmat A. J, Brix H. et al.(2019): Large-scale remediation of oil-contaminated water using floating treatment wetlands. Nature Clean Water 2,1-10.(IF:08)

- Hashmat, Amer Jamal, M. Afzal, Carlos A Arias, H Brix (2018). Characterization of Hydrocarbon-Degrading Bacteria in Constructed Wetland Microcosms Used to Treat Crude Oil Polluted Water. Bulletin of Environmental Contamination and Toxicology. DOI: 10.1007/s00128-018-2518-y

- M. Afzal, Hashmat, Amer Jamal, , H Brix et al (2018)."Large-scale remediation of oil-contaminated water using floating treatment wetlands", Springer Nature Publishing Journal (npj). Clean Water 2:3; doi: 10.1038/s41545-018-0025-7.

- Anwar ulHaq, Amer J. Hashmat et al. (2018) Pilot-Scale Electrochemical Treatment of Textile Effluent and its Toxicological Assessment for Tilapia (Oreochromisniloticus L.) Culture. Pakistan journal of zoology 50(5); 1703-17013. DOI: 10.17582/journal.pjz/2018.50.4.1703.1708.

- Irem, S., Islam, Hashmat, Amer Jamal et al. (2017). Adsorption of arsenic from drinking water using natural orange waste: kinetics and fluidized bed column studies. Water Science and Technology: Water Supply, ws2017009.

- Hashmat, Amer Jamal, et al. (2016). Integrated treatment technology for textile effluent and its phytotoxic evaluation. Desalination and Water Treatment, 57(9), pp.4146-4153.

- Hashmat, Amer Jamal (2015) Book title: Temporal Trends of Biosolid. LAP Lambert Academic Publishing; ISBN-13: 978-3659626487. Available online at http://www.amazon.co.uk/Temporal-Trends-Biosolids-Hashmat-Amer/dp/3659626481

- Sadiq, R., Hashmat, A. J. et al (2014). In vitro toxicological assessment of iron oxide, aluminum oxide and copper nanoparticles in prokaryotic and eukaryotic cell types. Drug and Chemical Toxicology, (0), 1-10.

|